Product display

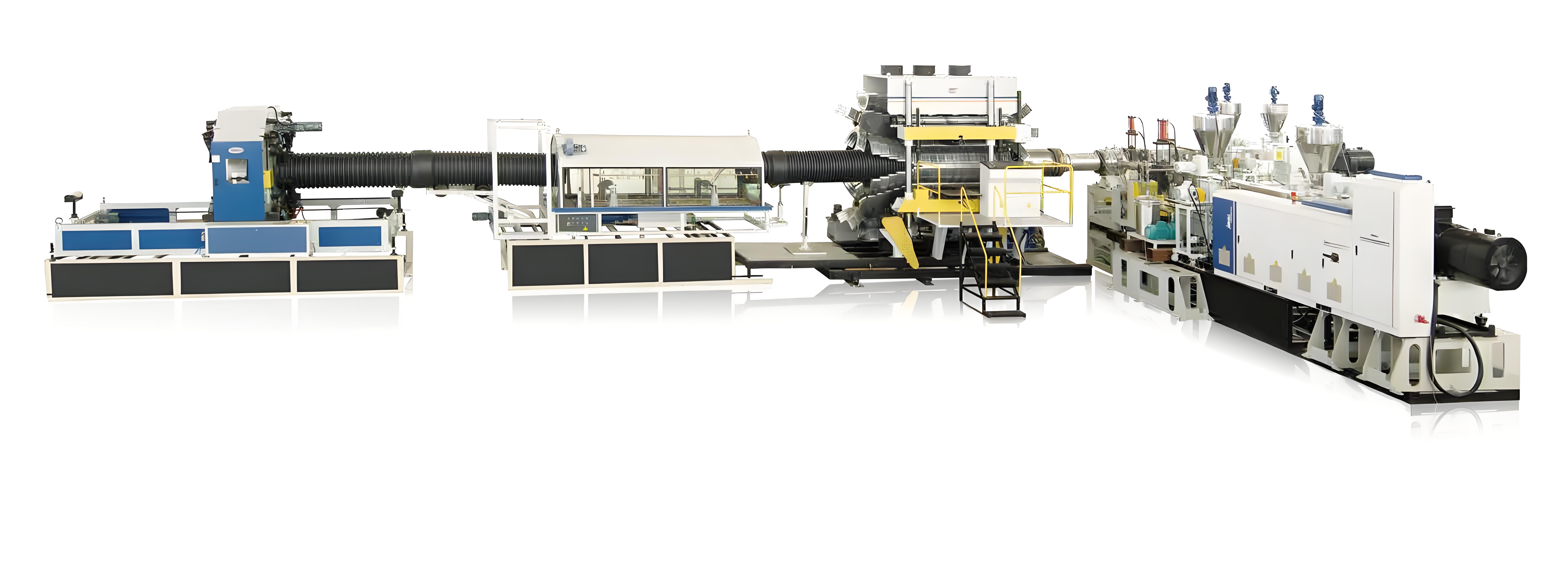

Vertical and horizontal shear composite line

- Commodity name: Vertical and horizontal shear composite line

Key words:

Vertical and horizontal shear composite line

- Product Description

-

Equipment Overview

The production line is a one-stop processing of cold and hot rolled steel coils for Kaiping, longitudinal cutting, winding, leveling, transverse cutting and flat stacking.

Standard configuration: feeding trolley, uncoiler, feeder, feeding pre-calibration machine, roller table transition table, limiting device I, longitudinal shearing machine, side wire winding machine, damping device, pressure dividing device, winding machine, discharging trolley, transition table, limiting device II, leveling host, storage bin, limiting device III, sizing machine, horizontal shearing machine, conveying workbench, pneumatic discharge rack, hydraulic lifting table, unloading system, hydraulic composition system, electrical control system.

The main components of the hydraulic system of the production line adopt Taiwan high-precision components, the electrical control adopts imported PLC program controller and touch screen to control the whole line of functions, the leveling main motor adopts DC motor, and the DC controller adopts the products of British European Company, which has the characteristics of high automation degree, high shearing precision, stable and reliable performance, convenient operation and maintenance, etc.

Specifications and parameters

Project Plate thickness Standard board width Uncoiler load-bearing Leveling accuracy Slitting line accuracy Unit operating speed Total power of unit Unit mm mm t mm/㎡ mm/m m/min kW Select range 1~6、3~12 1500、2000 30 ≤ 2.5 (standard plate) s±0.2 60,40 ~350、~450

Key words:

Get Quote

Note: Please leave your email address and our professionals will contact you as soon as possible!

Related Products