Product display

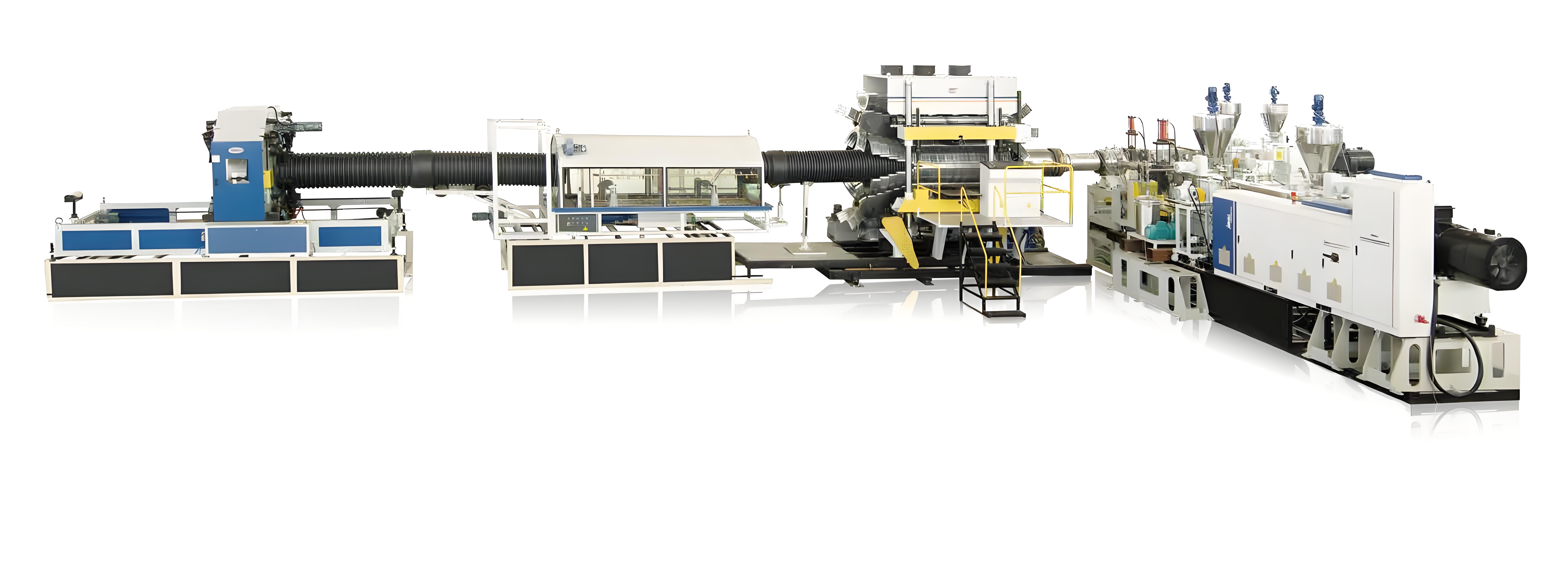

High speed single screw host extrusion PEPP double wall corrugated pipe production line

- Commodity name: High speed single screw host extrusion PEPP double wall corrugated pipe production line

Key words:

High speed single screw host extrusion PEPP double wall corrugated pipe production line

- Product Description

-

Performance and advantages: The corrugated pipe production line is the third generation of improved products of Suzhou Jinwei Company. The extrusion output of the main engine and the production speed of the pipe are greatly increased by 20-40% compared with the previous products. Can achieve online flaring, can ensure that the performance indicators of the corrugated pipe products after molding. The whole line of equipment adopts Siemens man-machine interface control system, which has stable extrusion performance, high degree of automation and simple operation.

1, the new design of the closed molding machine, the use of special molding aluminum module efficient cooling system, greatly improve the cooling efficiency in the production of bellows products.

2, high-speed, high-yield single-screw extrusion host, supporting the professional design of the bellows extrusion die, to achieve large output and stable extrusion.

3. The important parts of mass-produced molding machines have high precision and good module interchangeability. The molded aluminum module is made of LY12 high-quality alloy aviation aluminum material with copper content ≥ 5%. The precision pressure casting process has high density, bright, no pores, high strength, and is not easy to deform after long-term use. Various module waveform schemes can be customized according to user requirements.

4, supporting the full-automatic corrugated pipe cutting machine, computer program control, cutting position is accurate, stable operation and easy to use.

Key words:

Get Quote

Note: Please leave your email address and our professionals will contact you as soon as possible!

Related Products