Product display

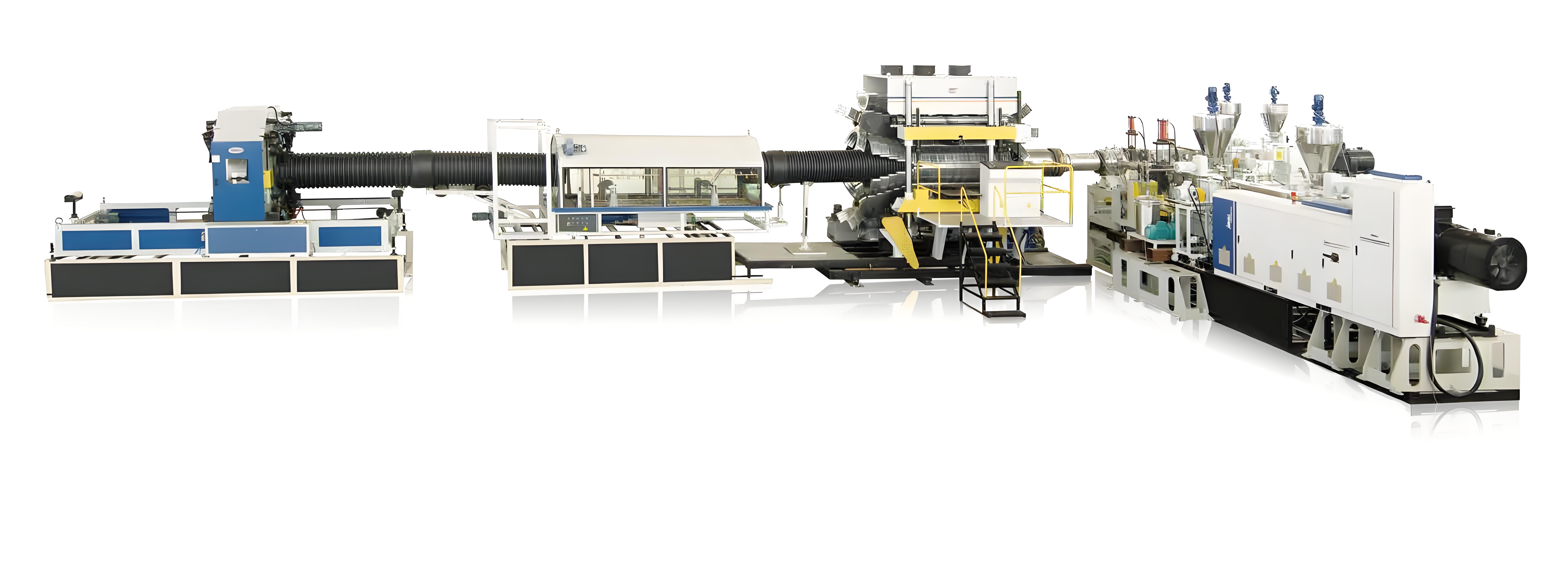

Shelf bottom plate cold bending production line

- Commodity name: Shelf bottom plate cold bending production line

Key words:

Shelf bottom plate cold bending production line

- Product Description

-

Equipment Overview

1. High production efficiency, low labor cost input

One-time realization of continuous production from the coil on the material to the single-piece forming line, high production speed, and only 3 minutes, you can change the production specifications in a short time. Using automatic industrial control technology, compared with the traditional decentralized multi-process multi-person processing, the whole line can only need one person to operate and patrol, which not only greatly reduces the number of operators from multiple to one, but also reduces the labor intensity and eliminates the need for manual handling and positioning. It also greatly reduces the ability requirements for operators and greatly reduces the labor cost.

2. Save materials, can produce box-type parts specifications

The use of numerical control stepless rapid adjustment of specifications technology, without the need to adjust the specifications after debugging, can save a lot of test machine waste due to the change of specifications, saving the cost of sheet metal input.

The production width range can be designed according to user requirements, steplessly adjustable; the width, length, and height range are designed according to user requirements; each parameter size is set by the operator.

Key words:

Get Quote

Note: Please leave your email address and our professionals will contact you as soon as possible!

Related Products