Dehua Trading

International trading company

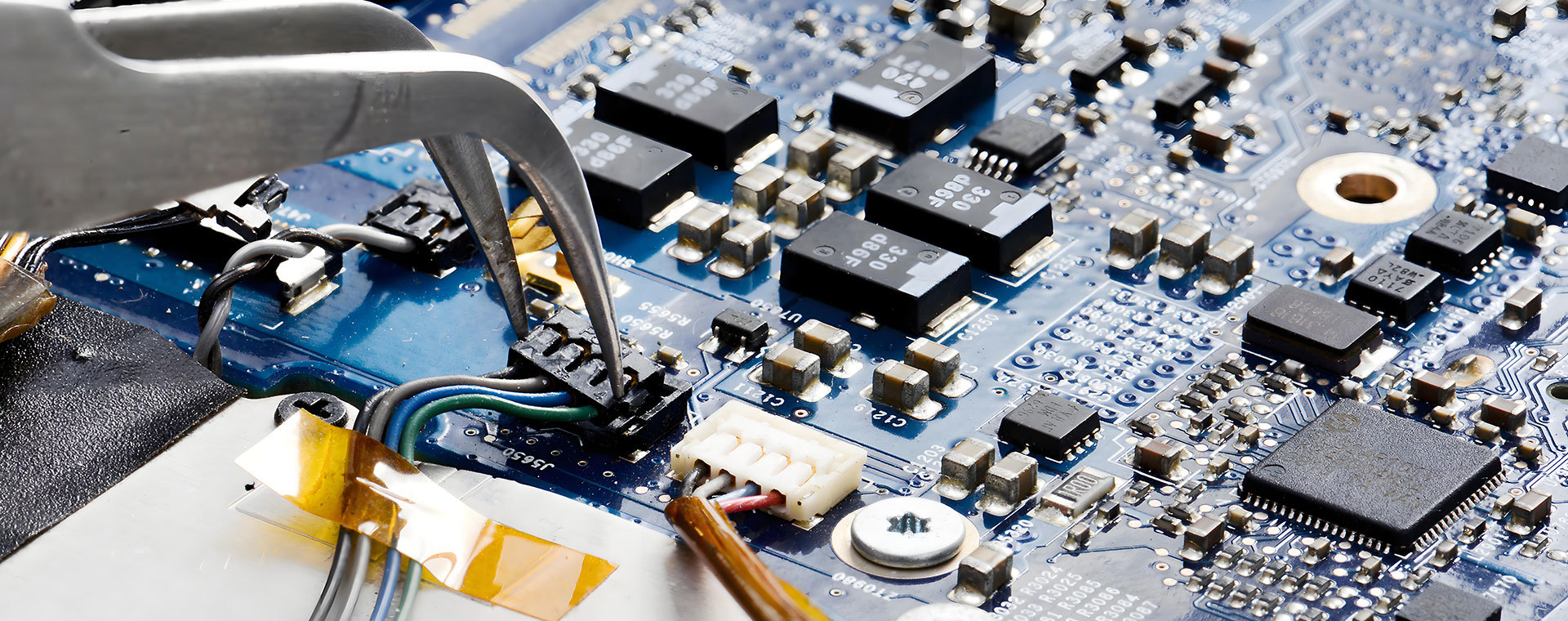

The main business direction is strip, steel pipe, automobile, heat treatment, metallurgy, wire manufacturing, plastic processing, electronic components, etc. The company's vision is to provide comprehensive services and technical support for industrial development in different countries. Group companies continue to develop new technologies, improve product quality and service levels to meet the different production needs of customers and better contribute to industrial development.

Warehouse area

Inventory varieties

Warehouse area

Application

The main business direction is strip, steel pipe, automobile, heat treatment, metallurgy, wire manufacturing, plastic processing, electronic components, etc.

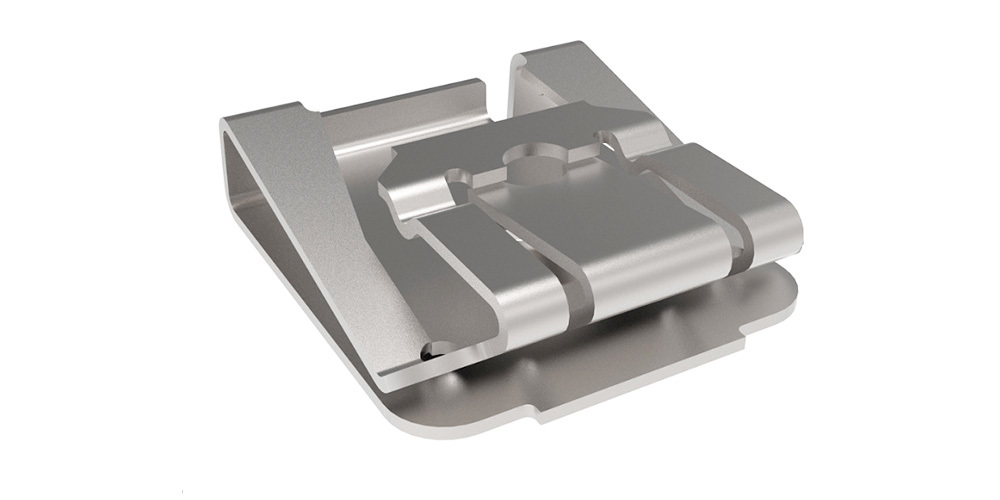

Recommend products

To provide users with cost-effective products and technical services, and share the blue ocean market with suppliers.

Technical strength

Comprehensive services and technical support for industrial development in different countries

We wholeheartedly provide our customers with a full range of technical support and services at all stages of business, including pre-sales technical consultation, various delivery services during sales and after-sales maintenance services, so as to ensure that customers are worry-free production and operate with peace of mind.

Our warehouses are located in China, Russia and other places. Based on the convenient transportation system, we can provide products and services to customers in different regions of the world.

More →Efficient work, quick response

After receiving the customer's demand information, we quickly process and formulate a plan to ensure that the products scheduled by the customer are delivered to the customer on schedule.

News

Record enterprise development information, let wonderful sharing

Teva Trading-International Trading Company

The company focuses on strip, steel pipe, automobile, heat treatment, metallurgy, wire manufacturing, plastic processing and electronic components and other business fields, and is committed to providing comprehensive industrial services and technical support.

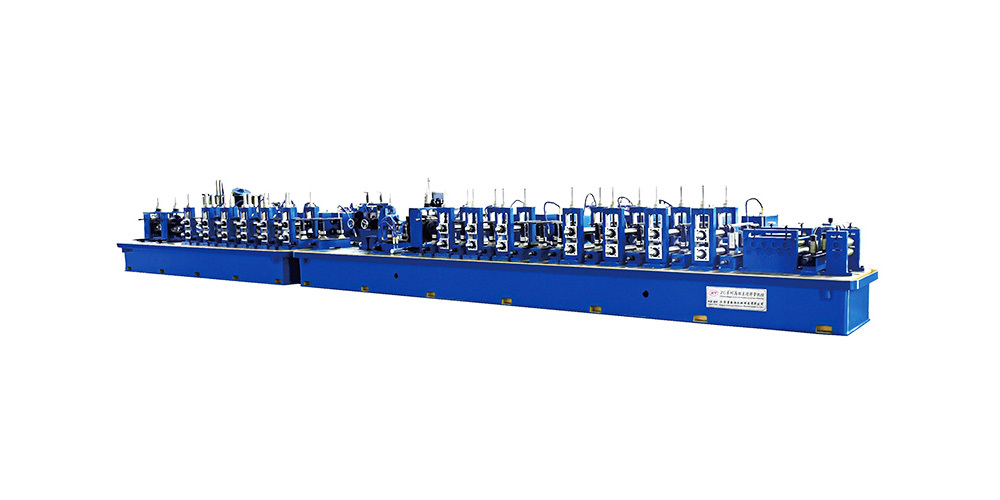

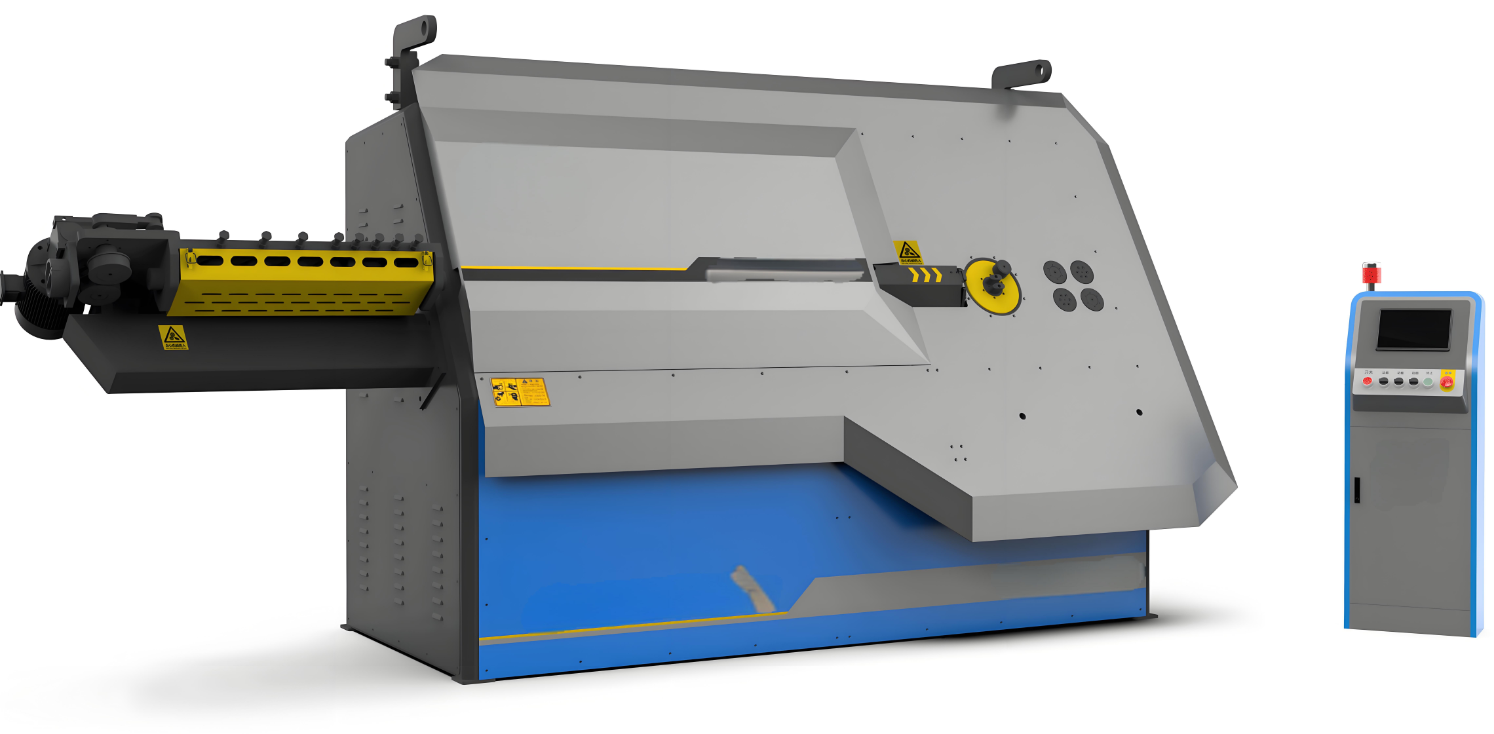

Spiral welded pipe unit as an efficient and automated steel pipe production equipment

The spiral welded pipe unit completes the production of steel pipes through a series of process steps. First, after uncoiling and leveling, the steel plate is rolled into a tubular shape by a forming machine. Subsequently, the welding machine performs spiral welding on the steel pipe, and the welding process uses high-quality welding technology to ensure the quality of the weld. The inner welding wheel frame and the outer welding wheel frame are respectively responsible for the welding of the inner and outer walls of the steel pipe to ensure uniform welding and no defects. Finally, the fixed-length cutting of the steel pipe is carried out by the flying saw machine, and the precision of the steel pipe is adjusted by the sizing machine to obtain the spiral welded pipe that meets the requirements.

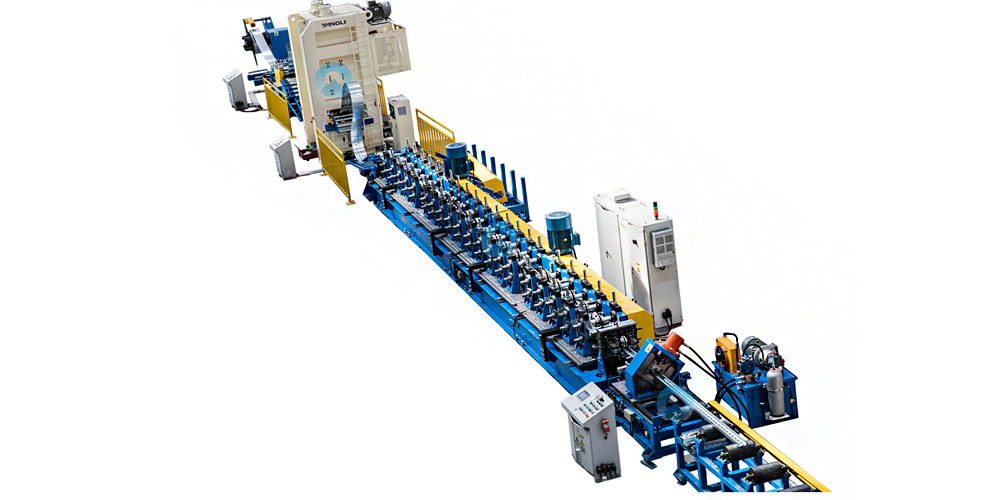

With the rapid development of the power industry and the continuous advancement of infrastructure construction, the market demand for the cold-formed production line of the power cabinet column will continue to grow. At the same time, the production line can also be used in other fields, such as construction, bridges, etc., and has broad application prospects.